Portfolio

Sand Casting Patterns

JP Pattern has ability to construct pattern tooling in various materials for low to high volume requirements. We also have experience with construction of pattern equipment for various types of sand molding and sand core equipment.

Investment (Lost Wax) Molds

Investment molds are one of JP Pattern's specialties. We have experience tooling parts from many different industries. From simple to complex, JP Pattern can offer innovative solutions for tooling which can lower overall cost to produce your castings.

Other Tooling Types

Our diverse customer base has helped become knowledgeable with a wide range of manufacturing methods. JP Pattern is not afraid to embrace new challenges in order to fill the needs of our customers.

Special Projects

Display and Training Models

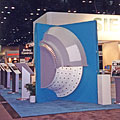

JP

Pattern constructed this model for use as both a display model and

training model. It exhibits the details and features of the

product and a model for

training. Working with our customer's engineering and marketing

departments we were able to add more value to the delivered product by

combining the training needs of engineering along with the trade show

needs of Sales and Marketing.

JP

Pattern constructed this model for use as both a display model and

training model. It exhibits the details and features of the

product and a model for

training. Working with our customer's engineering and marketing

departments we were able to add more value to the delivered product by

combining the training needs of engineering along with the trade show

needs of Sales and Marketing.

Aerobie Football

From prototyping to production, JP Pattern was able to understand the

objectives and respond with cost effective methods to meet our customer's

goals. Aluminum molds were used to create plastic molded shells, these shells were

then used to mold the foam product.

Hybrid Tooling

Combining manufacturing methods can sometimes yield new techniques to

achieve results. In this particular case RTV (rubber) is used to create

tooling used in a “near-net” casting of a

compressor casing. The rubber is shelled with ceramic in a dipping

process similar to lost-wax casting. The ceramic shell is then used for

centrifugal casting of the part.