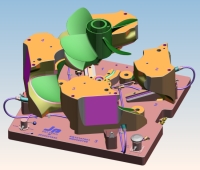

Foundry Tooling

Our experience with a wide variety of

foundry tooling types can help eliminate the need for multiple vendors

when bringing your products to market. We often find that techniques

applied in one manufacturing process can crossover to others. This

leads to a different and creative approach to tool design and

construction resulting in better parts and a cost-effective means of

producing them. JP Pattern has experience with creating tooling for

many metal casting industries such as investment (lost wax) molds or

dies, lost foam molds, high pressure die castings molds, low pressure

die casting molds, permanent molds, sand casting patterns, and

variations of these types.

Our experience with a wide variety of

foundry tooling types can help eliminate the need for multiple vendors

when bringing your products to market. We often find that techniques

applied in one manufacturing process can crossover to others. This

leads to a different and creative approach to tool design and

construction resulting in better parts and a cost-effective means of

producing them. JP Pattern has experience with creating tooling for

many metal casting industries such as investment (lost wax) molds or

dies, lost foam molds, high pressure die castings molds, low pressure

die casting molds, permanent molds, sand casting patterns, and

variations of these types.

Tool Design & Engineering

Comprehensive design approach to the construction of molds delivers cost effective results.

Investment Dies

One our our specialties here at JP Pattern is our ability to design and build investment or 'lost-wax' molds

Sand Foundry Patterns

JP Pattern can produce patterns many different types of molding machines with low volume and high volume outputs such as DISA, Hunter, BMD and others.

Other Tooling Capabilities

Working with our customer has expanded our capabilities. Meeting their needs has always brought forth interesting challenges that shaped the versatility of JP Pattern.