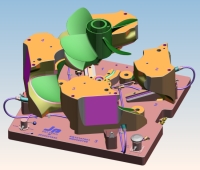

Tool Design and Engineering

Effective

tooling starts with a

comprehensive design approach. A designer must take advantage of

the manufacturing process as well as understand the difficulties

involved.

Effective

tooling starts with a

comprehensive design approach. A designer must take advantage of

the manufacturing process as well as understand the difficulties

involved.

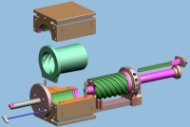

The steps we take at JP

Pattern first targets the CAD model

of the part. By applying the manufacturing process to the part, it

is then transformed into a master model.

This

master is then used to create

the tooling components necessary for the molding process. To

complete this step, quite often a mastery in CAD is an essential

trait that is needed with even some of the simplest forms of

geometry.

This

master is then used to create

the tooling components necessary for the molding process. To

complete this step, quite often a mastery in CAD is an essential

trait that is needed with even some of the simplest forms of

geometry.

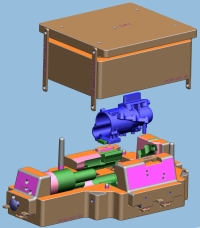

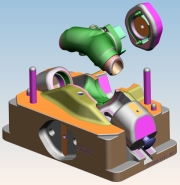

Tool components are

extracted from the master model and

must be shaped to allow for sound function as well as ease of

construction. Components need to interact with each other and be of

proper

size and proportion to create smooth flow as a mold reaches

each phase of molding process

cycle.

proper

size and proportion to create smooth flow as a mold reaches

each phase of molding process

cycle.

Lastly the design of the

tool

must take into consideration the equipment and environment in which

it will function.

When

this criteria is met the result is a well functioning

tool that will decrease time, increase product quality

and minimize cost throughout the manufacturing

process.

When

this criteria is met the result is a well functioning

tool that will decrease time, increase product quality

and minimize cost throughout the manufacturing

process.